Fortified Blended

Foods Plant

Economical Plants for

Energy Foods

Our extrusion-based FBF plants are the most economical production lines available on the market and are highly suited for both existing players wishing to expand and new entrants wishing to enter FBF production in Africa, South America and Asia where many of our plants are already in operation.

Range of Capacities:

We offer a choice of standard blended food solution lines:

- Automated plant: 1.2 Tons/Hour capacity

- Automated plant: 3.0 Tons/Hour capacity

- Manual blended foods line: 1 Tons/Hour capacity

- Custom-built to your capacity requirements

More Information on FBF Plants

- Extruder IP2000 Series

- Low installation height of only 135 – 220 mm

- About Fortified Blended Foods

- Why Choose Indopol?

- Registration of flow rate in t/h over 48 hours

- Joint Venture for New FBF Plant

- Interested? Get a quote…

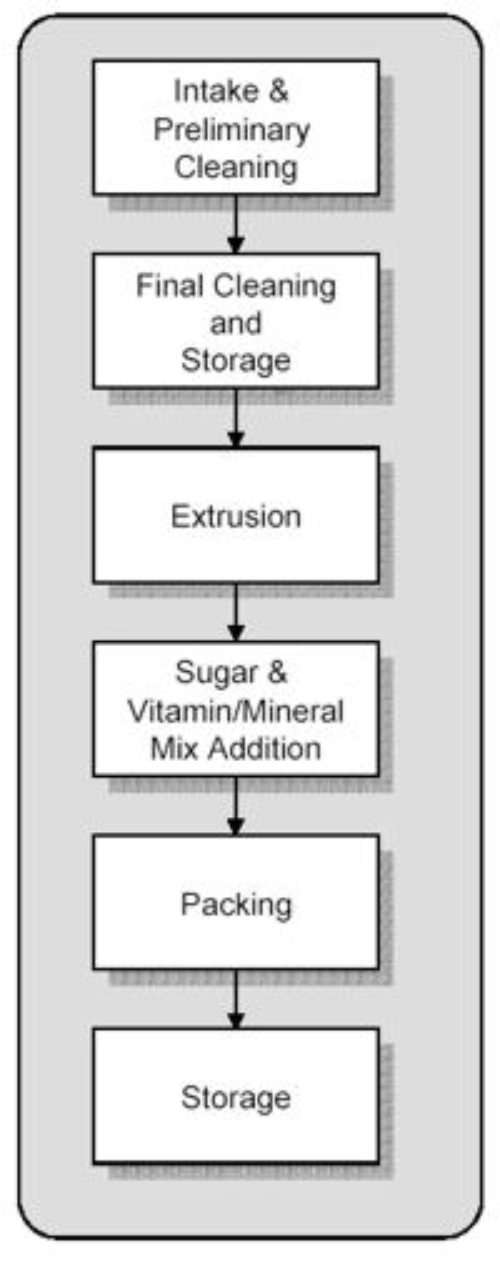

Production Process Overview:

- Intake & Preliminary Cleaning

- Final Cleaning & Storage

- Extrusion

- Sugar & Vitamin/Mineral Mix addition

- Packing

- Storage

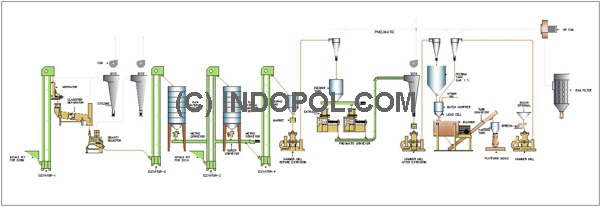

Intake & Cleaning

Extrusion

The extruded product is immediately cooled to ambient temperature and milled into fine flour.

Sugar & Mineral/Vitamin Mix Addition

The flour is homogenously mixed with the vitamin/mineral premix and (if applicable) sugar and/or oil.

Packing & Storage/Dispatch

The manufacturer notifies the quality control agency and the client when the batch is ready for quality control testing and shipment. Their representatives visit the manufacturer at the same time. The quality control agent takes a sample from the batch for testing in the agency’s laboratory. Together the agent and the client observe the product being loaded for transport and certify that the quantity is correct.