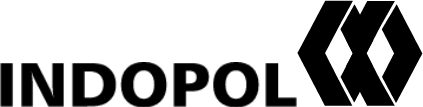

Flow Controller FC3

Gravimetric Dosage and Online Weighing of

Cereals and Free Flowing Bulk Materials

- Hydropneumatic controlled flat gate with integrated weigher

- Low installation height of only 135 – 220 mm

- Exact regulation of mass flow rate in kg/h

- Summation of total weight in kg

- Registration of flow rate in t/h over 48 hours

- % – input for grain compositions

- Simple mounting right below silos

Technical Specification

-

There are two versions available:

Type FC 3.15 for pipe diameter of 120 mm with flow rates of 0,2 – 15 t/h

Type FC 3.30 for pipe diameter of 150 mm with flow rates of 0,4 – 30 t/h - Height of both types: 135 mm with quadratic outlet, 220 mm with round outlet.

- Accuracy of the Flow Controller lies (depending of flow rate) at about 1 – 2%.

Reproducibility (implying steady flow rates) lies at 0,5 %.- Evaluation electronic:

Wall housing: 300 x 300 x 140 mm (B x H x T)

Panel mounting: 165 x 120 x 65 mm (B x H x T) - Evaluation electronic:

The 10 Point UNIQUE ADVANTAGE :-

- Proven Technology

- Economical Solution

- Reliable & Robust

- Maintenance-Free

- Made in Germany

- Simple Installation

- Insensitive to Vibrations

- High Capacity

- Versatile Installations

- Food Grade Applications

Function

- The Flow Controller FC3 is used for continuous regulation of cereals and other free-flowing materials.

- It consists of a measuring pipe with a glass insert (length of insert = 200 mm, diameter = 120, 150 or 200 mm). The device is normally installed in the run-off pipe immediately downstream of the flour worm. The measuring pipe is fitted with a special optical sensor which continuously measures the reflection of the flour being conveyed through the pipe. The degree of this reflection is always determined by the color or lightness of the flour.

- The evaluation unit of the monitoring system processes the measuring signal and establishes a mean value. This signal is shown continuously on a digital display. In case of a given grain mixture, it is also possible to compensate for the crude ash content of the flour. The measuring signal is automatically controlled by two adjustable limit values. It is possible to register the flour colour over a period of time by means of a recording unit. We also offer a RS 232/485 interface for data transfers and display of values on a Personal Computer.

- The constant display and control of the transient lightness value help to make the task of the mill supervision simpler and safer. A particular advantage of this system is the fact that flour sieve defects in the plansifter are immediately identified and relayed to the operator. Not only flour types, but also bran can be monitored constantly by this system. This means that milling errors can be identified immediately.

Evaluation

- The Evaluation and Control Electronic can be affixed entirely independent from the flow controlling unit. It is available for panel mounting or in a separate housing.

- Substantial evaluation and easy handling are possible through the application of a micro computer with LCD graphic display.

It provides the following functions:- Display of flow rate in kg/h

- Preset of a desired flow rate in kg/h or in %.

- Observation of flow rate by two adjustable limit values.

- Summation of total weight since last set to zero.

- Preselection of a desired batch in kg, reaching this weight affects the gate to be closed automatically.

- Extern start and stop function by sps-control activation.

- Output of kg-pulses for extern evaluation and processing.

- Analogue output of flow rate from 0 to 10 Volts.

- Graphic recording of flow rate over 48 hours.

- Alarm output for deviations in case of congestions or an empty silo.

- RS 232/485 – interface for communication with a computer.

- By application of a number of flow controllers it is possible to control compositions over the interfaces. Control of compositions can then be reached by a pc program or a master computer.