Automatic Dampening System NC6.2

Automatic Dampening System NC6.2

Exact moisture regulation of all kinds of cereals and grains

THIS IS EVERY MILLERS PROFIT MACHINE!!

- most economical & exact dampening system available

- applicable for all grain and cereal dampening systems

- successfully operating in more than 600 mills worldwide

- available with integrated flow weigher

- exact water dosage dependant on target moisture

- ATEX Compliant

- easy installation and extremely reliable

- average customer amortization within 3 months*

10 Point Advantage :-

- Profitable & Quick Payback

- Cheapest on the Market

- Reliable Operation

- Easy to Install

- Made in Germany

- ATEX Compliant

- More than 600 Installations

- Patented Technology

- PC Connection

- User Friendly

Overview

- With the automatic dampening system a mill can achieve optimal performance by maintaining it’s grain moisture at a constant and desired level.

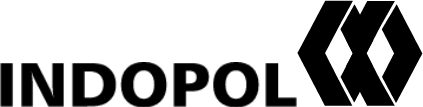

- The automatic moisture control system consists of three structural components, their internal mill installation may differ according to floor functions:

Display and registration

Display and registration of:

- grain moisture

- hectoliter weight

- grain temperature

- throughput rate

- water flow

Unit 1: Moisture Measurer

- The MOISTURE MEASURING UNIT containing bypass pipe must be installed upstream of the conditioning screw.

- Optional installation can be upstream of the latest elevator.

- The moisture measuring electrode is already wired in dust-free unit ( zone 20 licensed ) to avoid dust explosion.

Unit 2: MC6 Computer

The EVALUATION and CONTROL ELECTRONICS made of latest microprocessor technology with multilingual menu, containing the following functions:

- Display of the actual moisture ( % )

Display of hectolitre weight ( kg/hl ) and grain temperature ( C° ) - Calculation and display of the flow capacity by an integrated weighing system or by preconnected scale or dosing gate system ( kg ).

- Input of the desired target moisture

( optional six different types of cereals )

Calculation of water flow and its display ( litres/hour ) - Water dosing control with display of consumed water flow ( litres )

Display of actual moisture, of grain flow capacity and of water flow as a graphic presentation over a time span of 12 hours. - Limit value control of moisture, throughput rate, hectolitre weight and actual water

- RS 232/485 interface to connect with an external PC

Unit 3: Water Dosing Unit

The WATER DOSING UNIT can be installed anywhere along the water supply line of the conditioning screw and can be operated manually.

We offer two versions:

- water fittings on panel board

- water fittings in antifreeze box with thermo-regulated heating system

| Technical Specifications | |

|---|---|

| Supply Voltage | 110 - 230 Volt, 50/60 Hz |

| Measurement Range | 8 - 18% moisture, optimal for six different types of cereals |

| Capacity Range | 1 - 15 tons per hour, optional for higher capacities |

| Operating Temperature Range | 0-45°C |

| Display | Illuminated Graphic LCD Display (118mm x 90mm) |

| Operation Control | Dust-Protected Touch Panel Sensitive Menu-Driven Keyboard |

| Interfaces (optional) | RS 485 or RS 232, 20mA |

| Error Message | 2 relays max. 230 Volt, 2A |

| Water Dosing Unit | 1/2", max. 1600 liters per unit* |

| Required Water Pressure | 1 - 6 Bar, Interdependent on Flow Capacity & Water Column |

| Dimensions : Measuring Unit | Pipe Diameter 120mm Height (without Overflow Pipe System) 500mm Height (including Overflow or Bypass Pipe) 980mm |

| : Computer Control Unit | (W x H x D) 435mm x 340mm x 180mm |

| : Water Dosing Unit | (W X Hx D) 400mm x 600mm x 150mm |

| : Anti-Frost Box | (W x H x D) 550mm x 665mm x 210mm |